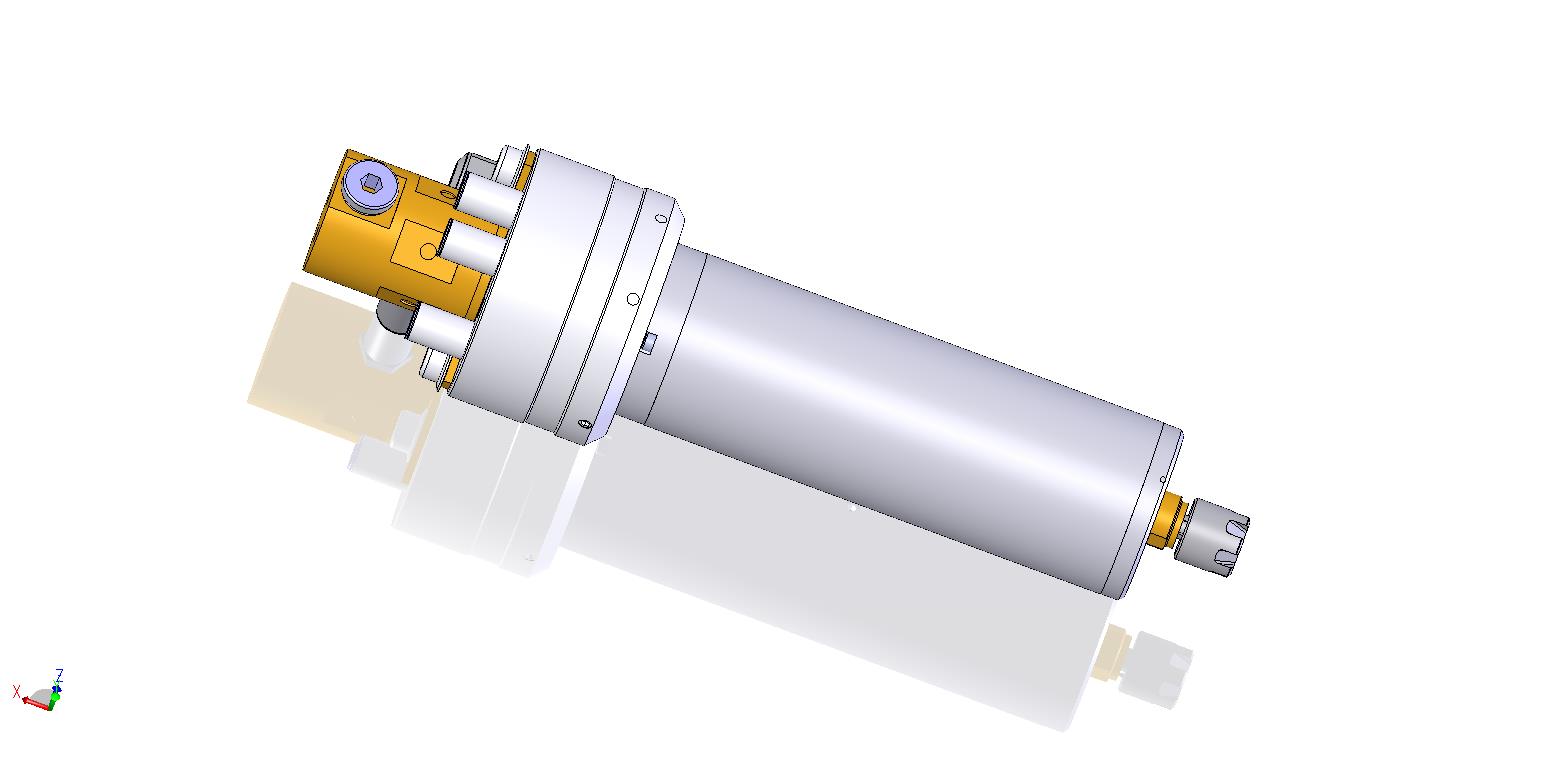

HF 45.11 S 35 CW

| Standard Option | HF The spindle motor is an asynchronous motor type. S The collet tooling system is standard for all motor spindles with manual tool changing. Note the spindle description and drawing for size and design. C Ceramic Hybrid Ball BearingsThe motor spindle is built with Ceramic Hybrid Ball Bearings. Option "C" is standard for most of IBAG motor spindles. W Tool Cooling through the spindle centreThe motor spindle is equipped with a Rotary Coupling for Tooling through the spindle centre. Option "W" is available for selected spindle types either with 80, 150 or 200bar. Option "W" is only available in combination with Option "H" and extends the motor spindle. Note the spindle description and drawing for details. |

| Additional Options | F Flange for axial mount of the motor spindleA flange on the housing enables an axial mount of the motor spindle. Note the spindle drawing for details. U Mega-xS Tooling System"U" is a high accuracy collet system with a runout in the collet of 1 μm. |

| Speed | Oil-Air (min-1) | 40'000 |

| CC-Grease (min-1) | ||

| Grease (min-1) | 40'000 | |

| Power | S6-40% (W) | 618 |

| S1 (W) | 475 | |

| Torque | S6-40% (Ncm) | 16.9 |

| S1 (Ncm) | 13 |

| Tooling system | Typ ER 11-UP |

| Frequency | (Hz) | 667 |

| Voltage | (V) | 170 |

| Current | (A) | 1.7 |

| Bearings | (Pce.) |

| Housing Diameter | (mm) | 45 |

| Spindle length | (mm) | 234 |

| Spindle weight | (g) | 2'001 |

| Way of cooling | Motor spindle with internal cooling to achieve highest power performance. The cooling temperature is between 24 – 26°C. |

| Alternative tooling systems | Typ MEGA 6S, |