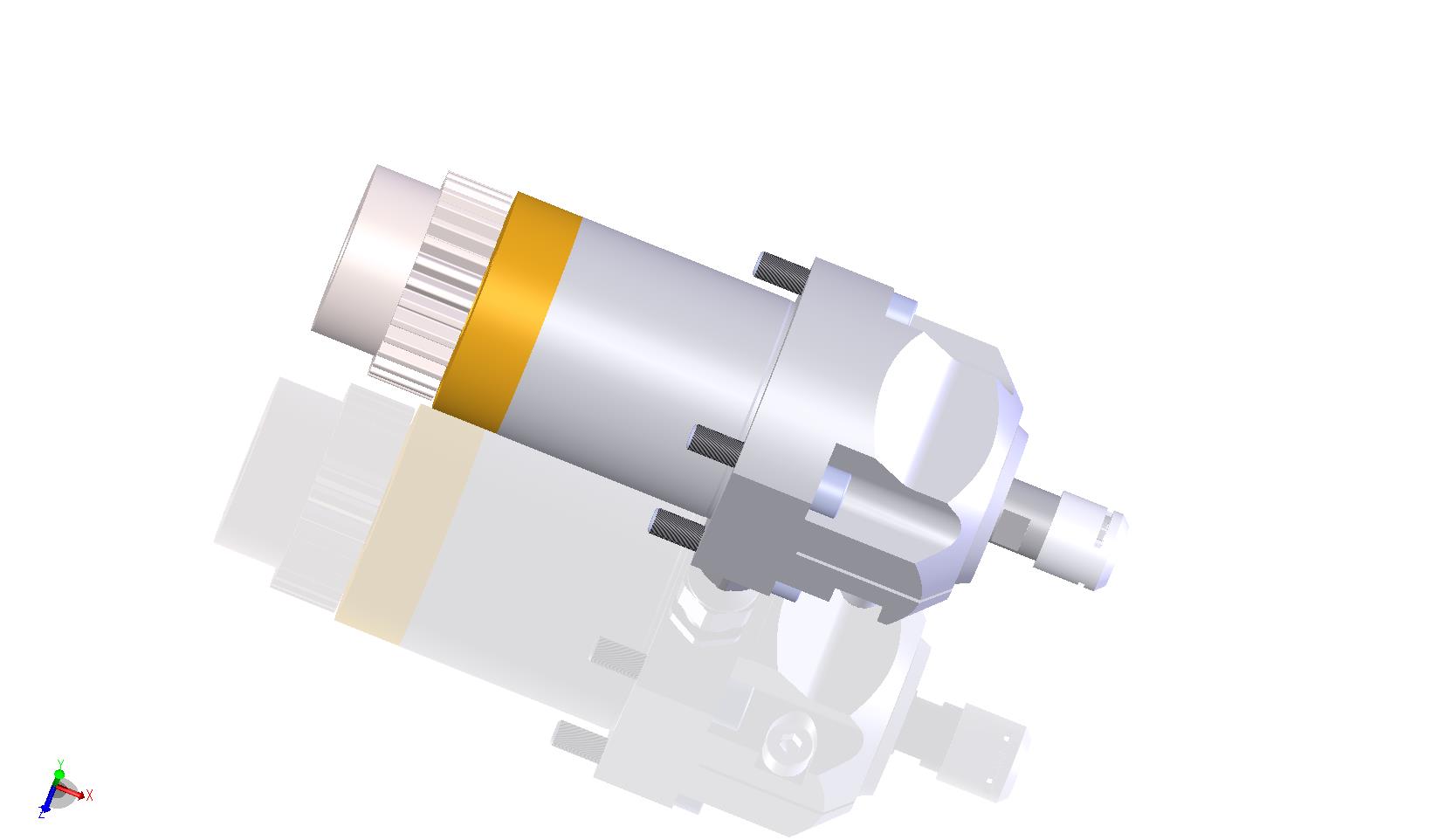

HTR 25.1 S 100 CPS

| Standard Option | S The collet tooling system is standard for all motor spindles with manual tool changing. Note the spindle description and drawing for size and design. C Ceramic Hybrid Ball BearingsThe motor spindle is built with Ceramic Hybrid Ball Bearings. Option "C" is standard for most of IBAG motor spindles. P Grease-packed ball bearingsThe ball bearings are greased-packed. Option "P" limits motor spindle maximum speed. Note the motor diagram for details. |

| Additional Options | C Ceramic Hybrid Ball BearingsThe motor spindle is built with Ceramic Hybrid Ball Bearings. Option "C" is standard for most of IBAG motor spindles. E Spindle Housing ExtensionThe housing of the motor spindle is extended. Note the spindle drawing for details. U Mega-xS Tooling System"U" is a high accuracy collet system with a runout in the collet of 1 μm. |

| Speed | Oil-Air (min-1) | 60'000 |

| CC-Grease (min-1) | ||

| Grease (min-1) | 40'000 | |

| Power | S6-40% (W) | 364 |

| S1 (W) | 280 | |

| Torque | S6-40% (Ncm) | 6.5 |

| S1 (Ncm) | 5 |

| Tooling system | Typ ER 8-UP |

| Frequency | (Hz) | 1'000 |

| Voltage | (V) | k.A. |

| Current | (A) | k.A. |

| Bearings | (Pce.) | 3 |

| Housing Diameter | (mm) | 25 |

| Spindle length | (mm) | 115 |

| Spindle weight | (g) | 718 |

| Way of cooling | Motor spindle without cooling. The Heat must be dissipated via spindle holder. Maximum external housing temperature is 60°C. |

| Alternative tooling systems | Typ MEGA 3S, |